When a four-storey healthcare project in Tāmaki Makaurau Auckland needed multiple seismic ties, TS Bricklayers’ director Tony Snaith needed a robust, seismic design – at the right price point. He took the problem to Masons. The result is Masons Q-Tie, a stainless steel, Type B veneer tie designed for movement, durability and straightforward installation.

Q-Tie: seismic brick veneer tie built for NZ conditions

‘For brick veneers over three storeys, we recommend a seismic-rated, tested tie,’ says Tony. ‘Because the tie has to allow movement, stainless steel is best. With galvanised, the coating can rub off at moving parts.’ Existing options also caused installation headaches: ‘Screws could hit the wire, which limited movement and slowed the job.’

Knowing Masons’ appetite for innovation, Tony contacted Key Account Manager Jacqueline Goldsbury. ‘We discussed where traditional ties were falling short for these large projects and mapped the ideal features for high-rise veneers,’ says Jacqueline. ‘Strong keying into mortar, a proper drip edge so water can’t track back to framing, and sensible screw spacings to make installation clean and quick.’

Designed with installers, for installers

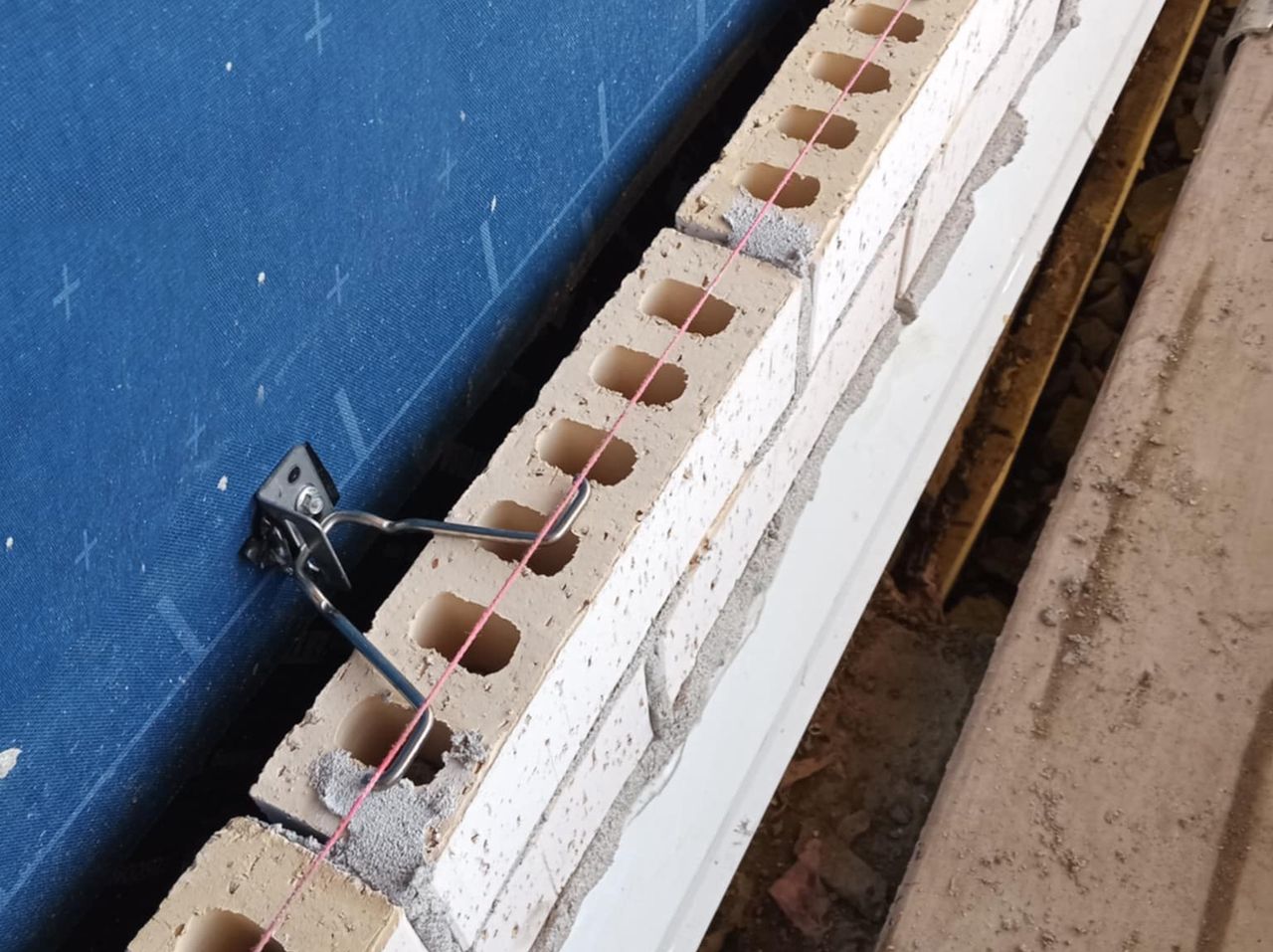

Masons prototyped and refined the concept with Tony on the tools. The outcome is Masons Q-Tie, a two-part system made from 5mm diameter 316 stainless steel wire with a base plate that allows clear access to screw holes (for up to 6mm concrete screws) before the wire is located. The moveable wire maintains the required freedom of movement while avoiding clashes with fixings.

A small but important detail is the 8mm drip edge: a groove that stops water tracking towards the building framing, supporting a dry, healthy wall build-up. ‘It sounds simple, but many ties don’t address that,’ says Tony.

‘The new Q-Tie is also more flexible to install than other ties,’ Tony notes. ‘You can even fix the bases before brickwork begins, which helps scheduling and keeps the site moving.’

Built for performance and longevity

Q-Tie is manufactured from 316 stainless steel for durability and corrosion resistance, addressing wear at moving interfaces that can compromise galvanised coatings over time. It is a Type B veneer tie, meeting seismic and wind-load requirements under NZS 3604, and has been fully verified by an independent New Zealand testing agency in accordance with AS/NZS 2699-1:2000.

For the healthcare project, Q-Tie did the job, reduced installation friction and delivered a cost-effective solution. ‘In the end, the tie worked perfectly, saved the client a lot of money and better served the building’s structural needs,’ Tony says. ‘And Masons has developed a new tie for the market, created specifically for our local conditions.’

‘The new Q-Tie is also more flexible to install than other ties,’ Tony notes. ‘You can even fix the bases before brickwork begins, which helps scheduling and keeps the site moving.’

Find out more

For specification and testing details, contact your Masons representative.

___

Project credits

Products: Masons Q-Tie

Bricklayer: TS Bricklayers

Writer: Folio