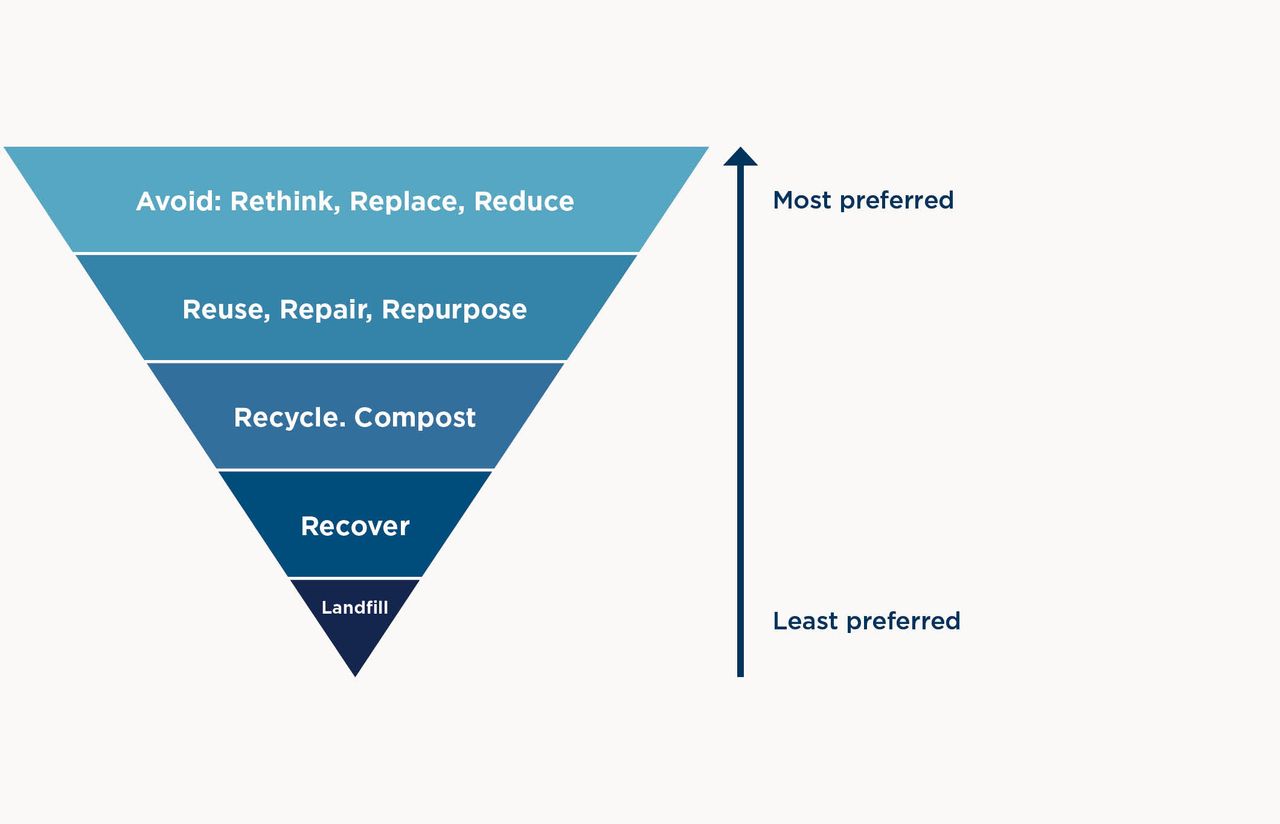

Recovery occurs when some value is extracted from the waste material. For example, using timber waste as firewood/heat recovers energy, but ultimately the resource is lost.

And finally, the last resort is landfill. Sending waste to landfill is least desired, because no value is recovered from the material, it takes up limited landfill space, and because it does not replace another product (through reuse and recycling), it does not reduce pressure on the Earth’s natural resources. Unfortunately, sometimes landfill disposal is the only safe way to dispose of some waste types, but that makes it all the more important to replace problematic materials with safer, recyclable alternatives.

Masons understands the importance of reducing waste to protect our planet, and their partnership with the Environmental Innovation Centre has enabled them to take meaningful steps toward more sustainable building practices.